Road Equipment Spare Parts

Spare Parts

Contact Us

What Road Equipment Parts Does Deruna Provide?

Excavator Parts

Loader Parts

Bulldozer Parts

Road Roller Parts

Crane Parts

Milling Machine Parts

Asphalt Finisher Parts

Dump Truck Parts

Excavator Parts

XCMG Excavator Parts

XCMG excavator parts can be primarily categorized as follows:

Core Components:

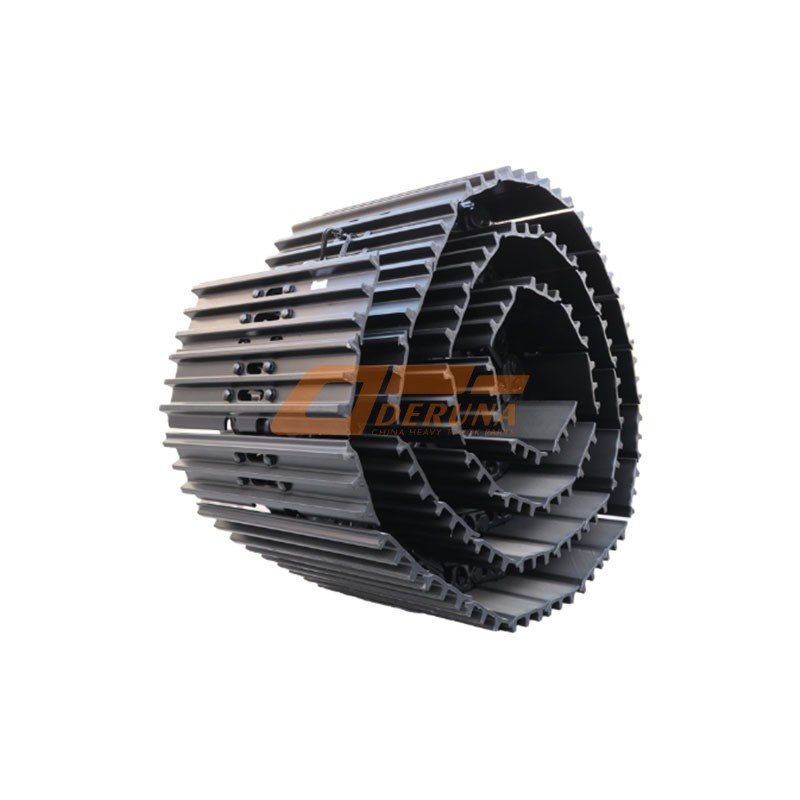

Includes hydraulic systems (e.g., hydraulic pumps, cylinders), engine components, undercarriage, and track systems. These form the power source and mobility foundation of the excavator, directly impacting its core performance.

Attachments and accessories: Examples include buckets, rippers, and hydraulic breakers, which expand the excavator’s operational capabilities.

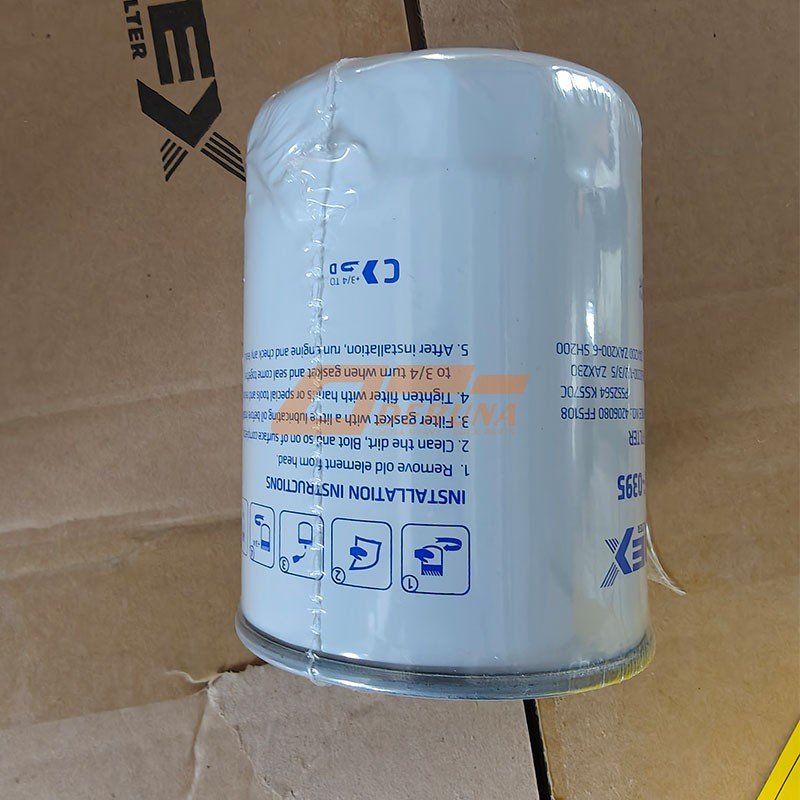

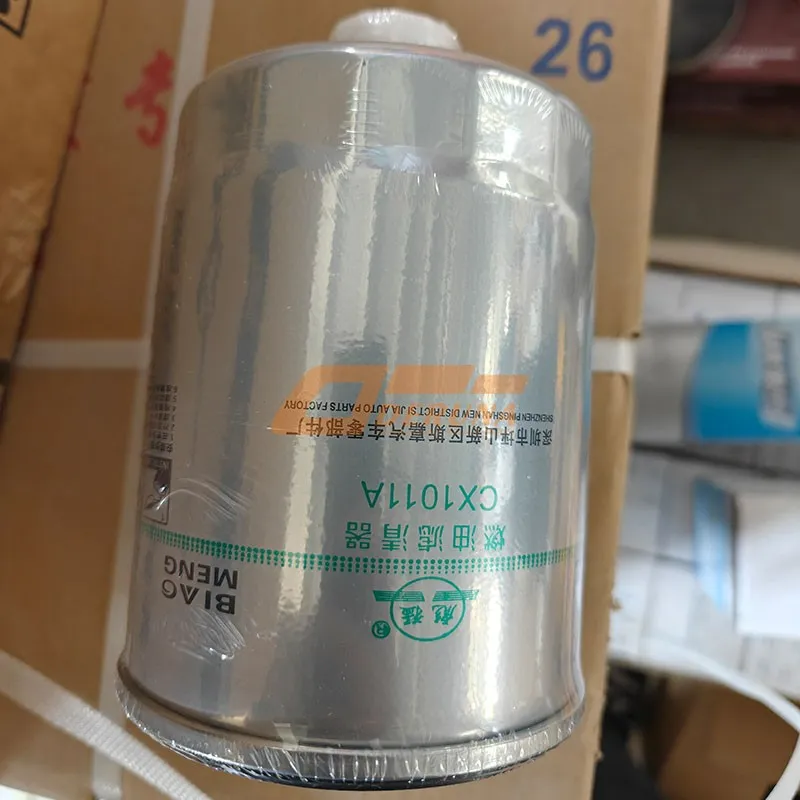

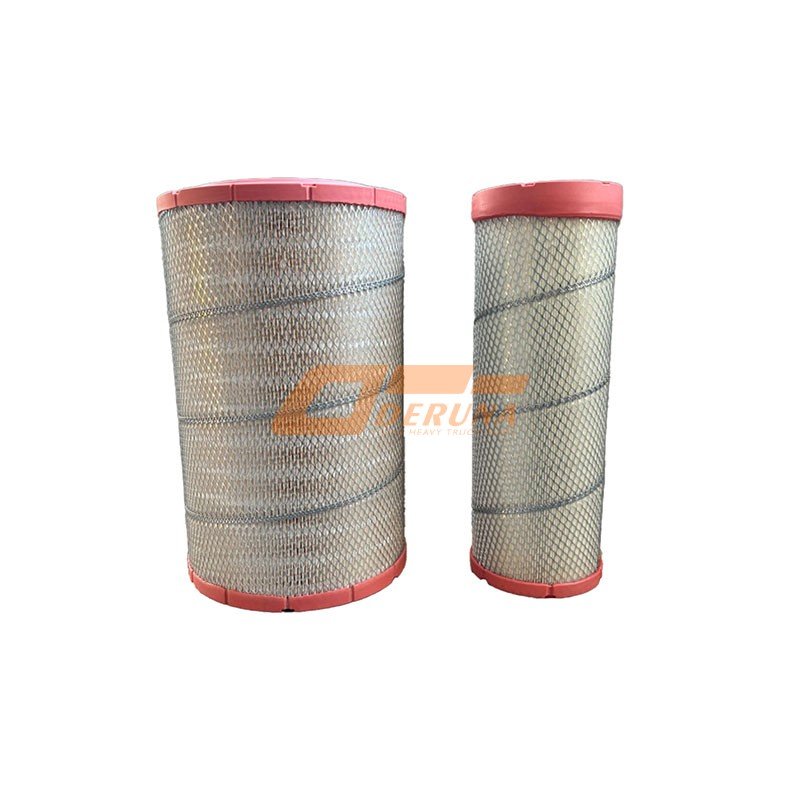

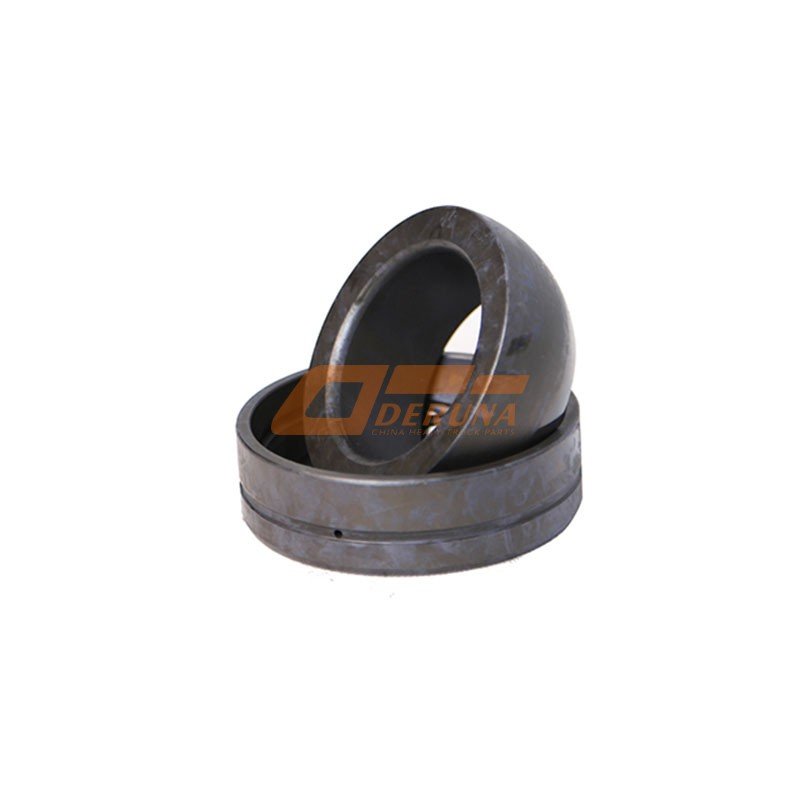

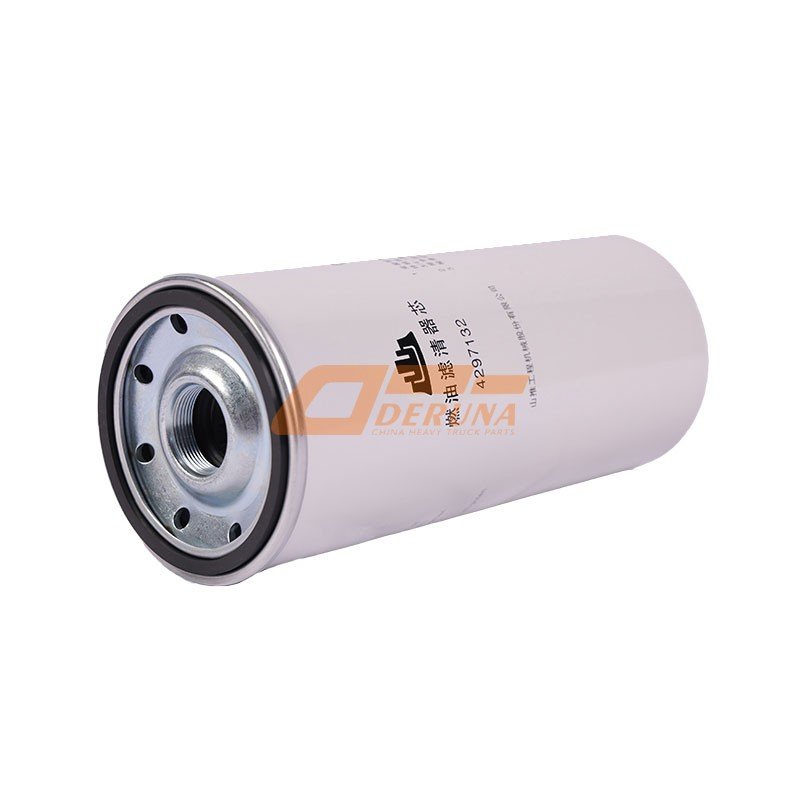

Wear parts and consumables: Such as filters, bucket teeth, track shoes, and seals. These components experience rapid wear during daily operations and require regular replacement to maintain optimal equipment condition.

Using XCMG genuine parts ensures perfect compatibility with your excavator model, preventing equipment damage or performance degradation caused by mismatched components.

800155719/800155718 Air Filter

800104393 Fuel Filter

Oil Filter 800159571

800151162 Fuel Water Separator

860548526 Hydraulic Oil Return Filter

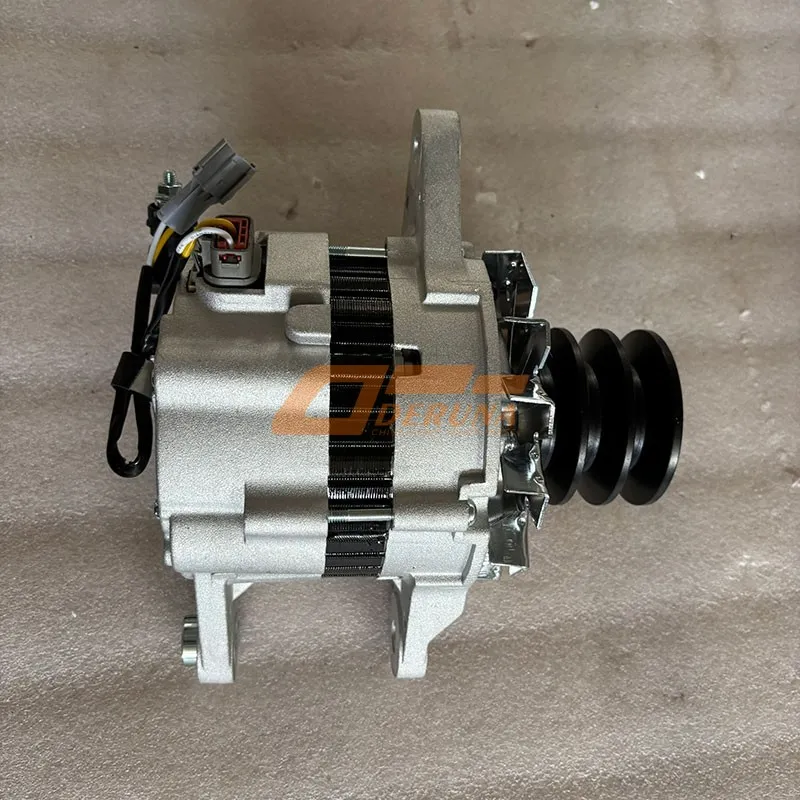

860582730 Alternator

860582729 Starter Motor

860575920 Water Pump

SANY Excavator Parts

SANY excavator parts are essential for ensuring your equipment operates efficiently and reliably. They **cover all core systems of the excavator**, including the **hydraulic system** (such as main pumps and cylinders), **engine-related components**, the **undercarriage track system** (like idlers and track rollers), and working attachments like **buckets and bucket teeth**.

These parts embody Sany Heavy Industry’s commitment to quality, typically crafted from **high-strength, highly wear-resistant materials** designed to withstand demanding conditions, thereby effectively extending the excavator’s service life.

Sany Diesel Filter 60320126

Sany Fuel Water Separator FS1098-GLQ008495953

Sany Hydraulic Return Filter 60193266

Sany AC External Air Filter B222100000660K

Sany Rearview Mirror 60117411

Sany Wiper Arm Blade Sy135-215-235-60128881

Sany Hand Rail 60071775

Sany Def Tank Assembly 160599000190A

Shantui Excavator Parts

Shantui Excavator Parts represents the professional strength of Shantui in the construction machinery supporting field, renowned for comprehensive coverage, reliable quality and broad adaptability. Its product portfolio spans core components including undercarriage parts (track rollers, track chains, drive sprockets), structural parts (boom, arm, bucket), engine accessories, and hydraulic components .

Crafted from high-grade raw steel and processed through stringent technologies like integral hardening heat treatment, key parts such as track rollers feature imported seal assemblies, enabling stable operation even in -50°C ultra-low temperature environments and harsh mining conditions . Backed by over 30 years of OEM supply experience and certifications including ISO 9001 and CE , these parts match the quality standards of international brands while offering a one-year to three-year warranty .

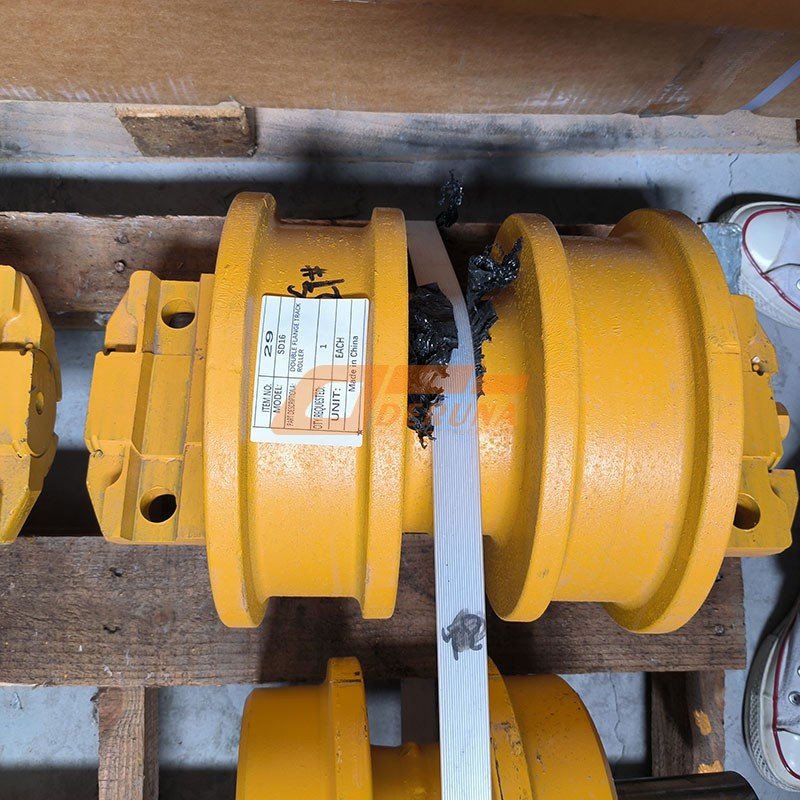

Track Roller Assembly

Track Plate

Track Assembly

Track Assembly

Support Roller

Main Pin

Guide Wheel Assembly

Chain Track Assembly

Zoomlion Excavator Parts

Zoomlion Excavator Parts embodies the comprehensive supporting strength of Zoomlion, a global construction machinery leader, and is favored for its full-category coverage, reliable performance and global service capabilities. Its product portfolio spans core components across multiple systems: structural parts including buckets, booms, and arms crafted with imported wear-resistant steel plates ; high-performance hydraulic components such as main pumps, plunger pumps, and bucket/boom cylinders featuring precision sealing and high-pressure resistance ; undercarriage parts like reinforced track rollers and hardened track shoes ; as well as essential accessories including radiators, oil coolers, and filters .

Quality is guaranteed by stringent manufacturing standards: key parts undergo integral quenching and tempering plus surface hardening , and the entire range is certified by ISO 9001, CE, and TUV . Backed by Zoomlion’s 30+ years of R&D experience in construction machinery , these parts deliver stable operation in harsh environments such as mining and high-temperature regions, with core components covered by a 1 to 3-year warranty .

Breaker Assembly

Bucket Teeth 9W8552RC

Bucket Tooth Seat LC450HD-50

Left Tooth 112-2488

Right Tooth 112-2487

Side Blade(Left) E200bl(096-4747)

Side Blade(Right) E200BR(096-4748)

Side Guard 166-2877-40

Loader Parts

XCMG Loader Parts

- XCMG Loader Parts embodies the technical prowess of XCMG, a global construction machinery giant, and is recognized for its full-system coverage, rigorous quality control, and efficient global service support.

- Its product portfolio spans core components across key systems of loaders: power transmission parts such as 6-blade turbine torque converters (boosting fuel efficiency by 15%) and forged axle assemblies with Rockwell hardness 58-62 HRC ; hydraulic system components including award-winning XOV25 multi-way valve castings (with valve hole bending degree <1mm) and chrome-plated cylinder rods (0.05μm surface finish) ; electrical modules like J1939-compatible CANbus controllers and -40°C to 150°C operational temperature sensors ; as well as structural parts such as 400 HB hardness abrasion-resistant bucket liners .

- Quality is rooted in decades of expertise: backed by 78+ years of R&D , every genuine part undergoes 23 rigorous inspections including material composition analysis and load cycle simulation . Manufactured with proprietary alloys and automated production lines (e.g., HWS/DISA intelligent molding systems) , key components like hydrostatic pumps (320 bar max pressure) and dust-proof alternators (IP69K rating) deliver stable performance in extreme environments such as mines and high-dust areas, with core castings validated by 200,000-hour bench tests .

- The full range is certified under ISO 9001 and IATF 16949 quality systems .

With precise compatibility, these parts are tailor-made for XCMG’s mainstream loader series, including LW300KV, ZL50G, and LW500FN , ensuring factory-grade fit and performance restoration. Relying on a global network covering 183 countries and regions , complemented by 46 overseas spare part centers and 3 billion RMB worth of standing inventory , XCMG enables near-instant delivery and 24/7 technical support via its official parts mall . Combined with lifetime technical assistance , it has become the preferred choice for loader maintenance and OEM matching worldwide.

Air Filter K2640

C85AB-1W8633AB Fuel Filter

C85AB-85AB302+B Fuel Water Separator

860159366 Brake Disc Pad

C06Bl-M7W5698+A Belt Tensioner Assembly

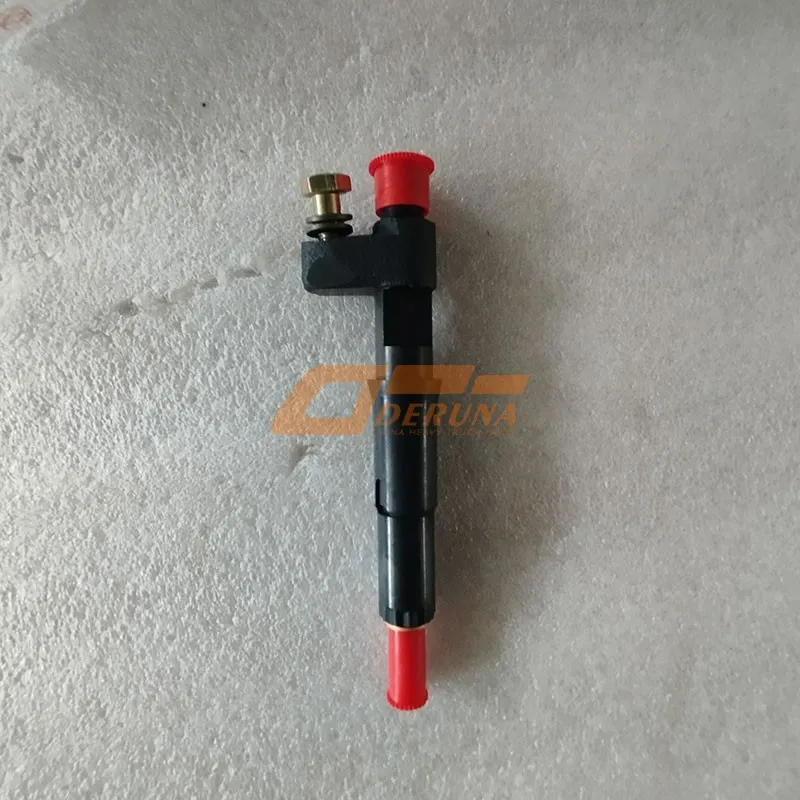

C26AB-26AB701 Fuel Injector

860114222 Gimbal Assy(Spider Assy)

S00017067+02+SH Alternator(Generator)

SANY Loader Parts

Includes transmission, hydraulic, and new energy modules (IP67 motors, liquid-cooled batteries), catering to both fuel and electric loader requirements; key components undergo 2000-hour endurance testing, capable of operating in extreme environments from -30°C to 50°C, with braking energy recovery technology reducing energy consumption by 18%; Compatible with Sany SW series (fuel-powered SW936K1, electric SW956E-Super); leverages a global network of 1,900+ service centers, 2,700+ engineers, and TVH spare parts partnerships to deliver efficient delivery and after-sales support.

Sany Brake Valve 60232819

Connecting Board Footboard 13486251

Sany Converter 60222546

Sany Fuel Fine Filter Core 60321274

Sany Fuel Sensor 60246822

Sany Pedal Assy SW405K1.1.8-13839425

Sany Safety Catridge Of Air Filter 60207264

Sany Video System Display 60105154

Shanui Loader Parts

Shantui loader parts are manufactured by Shantui based on decades of industry expertise, offering core advantages in heavy-duty durability, comprehensive system coverage, and high cost-effectiveness. Key features include:

- Full System Coverage: Encompasses core components of the loader’s critical systems, including: Hydraulic System (25MPa high-pressure gear pumps, integrated multi-way valves with ≤0.5% pressure loss, chrome-plated cylinders with 0.08μm surface precision), structural wear parts (Mn13 high-manganese steel 400HB wear-resistant bucket liners, fully welded reinforced boom, anti-slip tires), and electrical auxiliary components (voltage regulator compatible with -30°C to 80°C, IP67 waterproof sensors, aluminum alloy radiator with 15% higher cooling efficiency), meeting both routine maintenance and overhaul requirements.

- Rigorous Quality Assurance: All genuine parts are manufactured to Shantui OEM standards, undergo 16 quality inspections (including material analysis, pressure cycle simulation, and low-temperature start-up testing), and are ISO 9001 certified. Core components (such as drive axles and hydraulic pumps) withstand harsh environments like open-pit mines and high-dust conditions, backed by a 1-2 year warranty.

- Precision Compatibility & Efficient Service: Precisely matched to Shantui’s mainstream loader series (3-ton SL30W, 5-ton SL50W, 6-ton SL60W), ensuring 100% factory-level fitment and operational efficiency. Leveraging a domestic service network covering 31 provinces and municipalities, along with overseas distribution centers in Southeast Asia, the Middle East, and Africa, we deliver timely parts supply and 24/7 technical support. This makes us a reliable choice for loader users in construction, mining, and logistics industries.

Air Boost Pump

Bucket Teeth

Frame And Boom Rear Axle

Loader Tires (Standard Edition)

Pilot Twin Pump

Right Tooth

Steering Cylinder

Working Pump

Zoomlion Loader Parts

Zoomlion loader parts are professional accessories developed by Zoomlion, a global leader in construction machinery. Their core strengths lie in comprehensive system coverage, robust heavy-duty performance, and intelligent compatibility. These advantages can be summarized in three key aspects:

- Comprehensive System Product Matrix: Covers core components of loader critical systems, including: Hydraulic System (31.5MPa high-pressure main pump, corrosion-resistant chrome-plated integrated manifold valve, imported sealed cylinders with high-temperature leak resistance), Structural Wear Components (NM450 wear-resistant steel bucket liners with twice the lifespan of standard steel, stress-relieved welded boom for enhanced durability, puncture-resistant construction tires for gravel applications), and intelligent electrical components (CAN bus controller compatible with Zoomlion’s smart maintenance platform, sensors adapted for -35°C to 85°C temperature range, high-efficiency thermally controlled electric fan). These features meet diverse loader maintenance requirements across industries.

- Rigorous Quality Assurance: All genuine parts manufactured to Zoomlion OEM standards, undergo 18 inspections (including material spectral analysis, heavy-duty cycle testing, low-temperature endurance verification), and certified to ISO 9001, CE, and TUV. Core components (e.g., wet brake axles, hydraulic pumps) withstand harsh conditions like high dust and continuous heavy loads, backed by 1-2 year warranties.

- Precision Compatibility & Global Service: Precisely matched for Zoomlion’s mainstream loader series (5-ton ZL50GV, 3-ton LW300FV, 6-ton ZL60G), ensuring 100% factory-level fitment and operational efficiency. Leveraging a global service network (with local parts warehouses in Southeast Asia, Europe, and South America, plus domestic coverage across 32 provinces), we deliver timely parts and 24/7 technical support, making us the reliable choice for loader users worldwide.

Water Filter Cartridge NP0203030031

Safety Filter Cartridge A02-03720

Respirator Filter Cartridge PO-CO-02-02760

Pilot Filter Element PO-CO-02-02790

Oil Filter Element PF-CO-01-031100

Fuel Filter Element FO1-01310(6)

Fuel Coarse Filter Element NP0203020109

Boom Cylinder(ZL21-DB) Repair Kit

Bulldozer Parts

XCMG Bulldozer Parts

- XCMG bulldozer components form an exclusive parts system developed by XCMG Group, a global leader in construction machinery, for its bulldozer series. Leveraging the Group’s 78 years of R&D expertise and manufacturing prowess in the construction machinery sector, this system delivers OEM-quality parts solutions for demanding applications such as large-scale earthmoving operations. As a vital component of XCMG’s comprehensive construction machinery parts ecosystem, this series covers core bulldozer systems and wear-prone components, compatible with multiple mainstream models. It serves as a critical foundation for ensuring efficient equipment operation.

- Centering on stringent quality control, every genuine part undergoes 23 rigorous inspection procedures. These include material composition analysis, load cycle simulation testing, validation under extreme temperatures from -40°C to 65°C, and vibration resistance certification. Compliance with international standards like ISO 9001 and MIL-STD-810G ensures enduring durability in harsh environments like mining and infrastructure projects. Core offerings span three critical systems: – Power transmission components like specialized transmissions and forged gears utilize proprietary alloy materials and innovative transmission configurations to enhance transmission efficiency and fuel economy. – Hydraulic system components, including high-precision cylinders and load-sensing control valves, feature chrome-plated piston rods with 0.05μm surface finish and <3ms response times to guarantee operational precision. Additionally, the portfolio includes weather-resistant electrical controllers, sensors, and undercarriage components like track assemblies and idler wheels, comprehensively addressing equipment maintenance needs.

- Leveraging XCMG’s global service network, XCMG Bulldozer Parts delivers genuine compatibility assurance, lifetime technical support, and efficient worldwide distribution. Its quality and compatibility not only extend bulldozer lifespan and reduce downtime costs but also demonstrate XCMG’s self-reliant technological prowess in core components, making it a trusted choice for global users to maintain equipment performance.

Bulldozer Cab Drive Cabin

Air Suspension Seat

Gearshift Valve 16Y-75-10000

Bit End 16Y-81-00002/16Y-81-00003

Monitor Display Monitor Panel

Pinion Shaft 154-15-33240

Universal Joint Assy 16Y-12-00000

Shaft Coupling 16Y-15-00009

SANY Bulldozer Parts

- SANY Bulldozer Components is the original equipment manufacturer (OEM) parts system developed by SANY Heavy Industry for global earthmoving projects. Leveraging the Group’s core R&D capabilities in construction machinery and its global manufacturing footprint, it delivers compatible and durable component solutions for demanding applications in mining, infrastructure, agriculture, forestry, and water conservancy. As a core component of SANY Construction Machinery’s full lifecycle service, these parts cover critical systems including bulldozer power, hydraulics, and undercarriage, serving as the essential foundation for sustained, efficient equipment operation.

- This series leverages “technology integration + stringent quality control” as its core strengths. All genuine parts undergo multidimensional performance validation and comply with international quality standards such as ISO 9001 and TS 16949. Core components leverage global premium supply chain resources, including Rexroth hydraulic pumps and valves, Cummins engine-specific assemblies, and Sany’s proprietary planetary gearboxes. The latter incorporates Schaeffler bearings and specialized alloy steel treated with carburizing and quenching processes, achieving industry-leading gear precision and load-bearing capacity. For extreme operating conditions, wear-prone components like dozer blades and track pads utilize Hardox 500 special wear-resistant steel with impact-resistant coatings. Combined with Sany’s patented dual-telescopic arm hinge structure for dozer blades, this enables flexible multi-angle operation and extends service life by over 30% compared to conventional parts.

- In terms of product coverage, three core systems have been established: – Power transmission components like transmission assemblies and forged gears utilize full-power matching technology to optimize fuel efficiency; – Hydraulic system components, including high-precision cylinders and load-sensing control valves, ensure operational precision with response times under 3ms; For chassis systems, track assemblies and idler wheels feature monocoque bogie designs that minimize soil accumulation and travel wear, achieving a theoretical lifespan 1.2-1.5 times longer than domestic competitors. Additionally, the dedicated lubricant series (engine oil, hydraulic oil, etc.) employs precision formulations to reduce equipment failure risks and maintenance costs.

Carrier Roller

Double Flange Track Roller

Engine Oil Dipstick

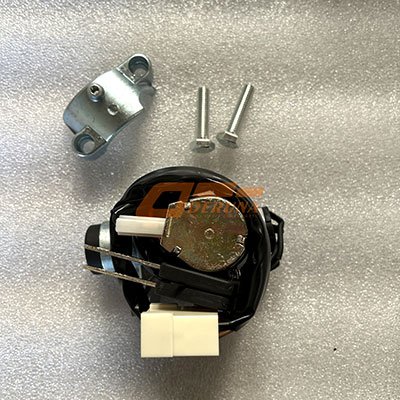

Excitor

Fan Belt

Generator

Starter Motor

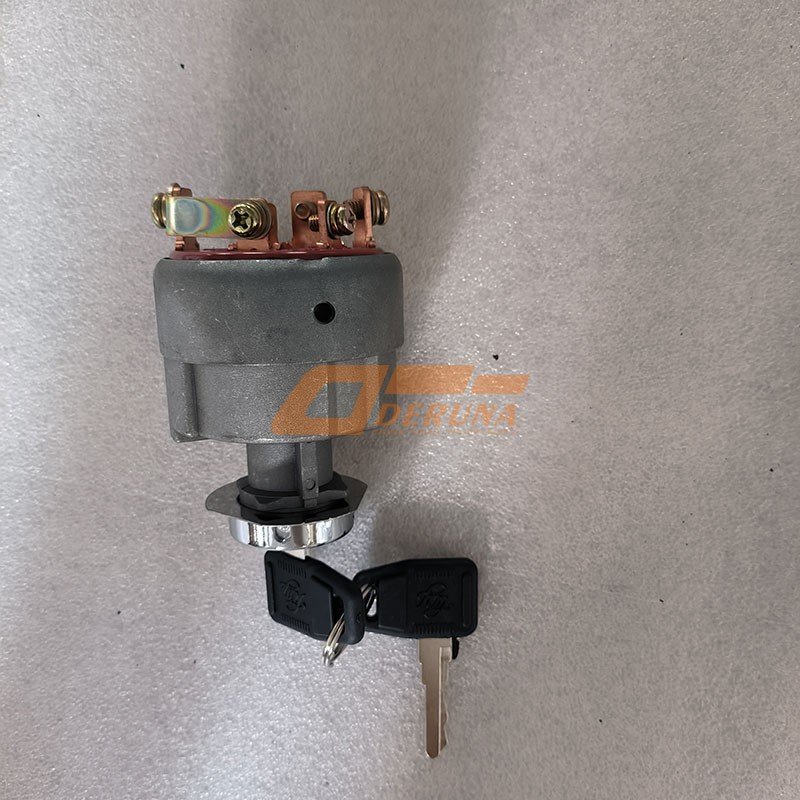

Start Switch

Shantui Bulldozer Parts

- Shantui bulldozer components form an original equipment manufacturer (OEM) parts system developed by Shantui Co., Ltd. leveraging over 70 years of construction machinery expertise and Shandong Heavy Industries’ “golden industrial chain.” This system delivers solutions that combine adaptability and durability for demanding environments like mining and infrastructure projects, serving as the core operational support for over one million Shantui machines worldwide.

- Its core strengths lie in proprietary technology and comprehensive quality control across the entire supply chain: The transmission system features key components like the SD52 modular transmission assembly (equipped with a dual-clutch lock-up torque converter, reducing overall fuel consumption by over 5%) and the YJ365 torque converter (with tensile strength exceeding industry standards by 20%). The undercarriage system sets benchmarks with its full range of lubricated tracks (50% longer lifespan than traditional tracks, holding 10 patents), China’s largest 350mm pitch tracks (exceeding 15,000 hours in rock conditions), and fully hardened mining-grade “four-wheel” components. Seal reliability and wear resistance are reinforced through multiple manufacturing processes. Product categories cover critical systems including powertrain, hydraulics, and undercarriage, compatible with the full range of SD08 to SD90 models from Shantui, as well as equipment from leading brands like Komatsu and Caterpillar.

- Service support leverages a global network of “port backbone warehouses + regional hub warehouses” spanning over 120 countries and regions. Domestic coverage includes a 2-year/3,000-hour warranty, extended to 18 months overseas, complemented by 48-hour response times and parts consignment policies to significantly reduce downtime costs. Its technical prowess and reliability have been validated in extreme environments across over 95% of Belt and Road countries, Canadian mines, and African infrastructure projects, achieving import substitution for multiple core components.

TP1000588583 Air Filter

TP1000442956 Fuel Filter (Fine Filter)

TP612600114993 Fuel Filter

16Y-15-07000 Transmission Magnetic Filter Element

Tooth Tip

Transmission Control Valve

Universal Joint Assembly

Belt Tensioner Pulley

Road Roller Parts

XCMG Road Roller Parts

- XCMG roller components constitute an original equipment manufacturer (OEM) parts system developed by XCMG Group leveraging its technical expertise in road machinery. This system delivers tailored solutions for full-spectrum compaction operations across high-grade highways, airports, ports, and other applications. Compatible with the entire range of XCMG roller models—including XS series single-drum, XD series double-drum, and XP series pneumatic-tire rollers—the components also support select international brands.

- Its core competitiveness lies in intelligent technology integration and full-chain quality control: Key components like the patented cylinder-type four-support structure vibrating wheel employ oil-spoon lubrication and shock-free exciter technology, achieving a lifespan exceeding 10,000 hours to withstand harsh conditions; The independently developed GJ850D hydraulic cylinder boasts a yield strength exceeding 850MPa, achieving a 15% weight reduction while increasing working pressure by over 10%. Paired with a dual-pump, dual-motor drive design, it eliminates operational vibration. All genuine components comply with ISO 9001 quality standards and relevant national regulations, withstanding extreme temperatures from -40°C to 120°C and operating on slopes up to 35%.

- Product categories span four major systems: power transmission, hydraulics, vibration, and undercarriage. This includes over 2,000 parts such as SPT-3 spray nozzles, vibration motors, steering cylinders, and transmission assemblies, precisely matching flagship models like the XS265JSIV and XP163.

800358963 Drive Disc Assembly(Clutch Plate)

800358962 Cover(Pressure Plate)

801540478 Side Mirror(Right)

612600114993 Air Filter

803164589 Filter Element(HYD Suction)

D11-102-13 Alternator

S00013524+01 Starter Motor

860517051 Clutch Release Bearing

SANY Road Roller Parts

Sany roller components constitute an original equipment manufacturer (OEM) parts system developed by Sany Heavy Industry, leveraging core technologies in road machinery and global manufacturing capabilities. This system delivers efficient, durable component solutions for comprehensive compaction operations across high-grade highways, airports, mines, and other scenarios. Covering critical systems including power transmission, hydraulics, vibration, and undercarriage, these parts are compatible with the full range of models, including the SSR series single-drum and SR series double-drum rollers. Through technological innovation, they also achieve compatibility and substitution for equipment from international brands.

Core Technology and Product Advantages:

- Key components developed in-house and manufactured through global supply chain collaboration—such as planetary gearboxes—incorporate Schaeffler bearings and proprietary alloy steel treated with carburizing and quenching processes. This achieves industry-leading gear precision and load-bearing capacity. Hydraulic system components (e.g., high-pressure cylinders) are developed in deep collaboration with Rexroth, delivering response times ≤3ms and over 10% increased operating pressure. Vibratory wheels employ oil-cup lubrication technology, tested through 100,000 load cycles with a comprehensive lifespan exceeding 10,000 hours, accommodating multi-frequency compaction demands from 27-32Hz.

- The integrated intelligent compaction system employs high-precision positioning, temperature sensors, and a big data cloud platform to monitor compaction density, pass count, temperature, and other parameters in real time. It generates visual color-graded maps to guide operations, significantly enhancing construction uniformity and quality. For instance, on a Nanjing expressway project, sections using Sany’s intelligent compaction technology achieved 20% lower compaction density variability and 15% improved structural depth uniformity compared to traditional methods. The C10+ series launched in 2025 further upgrades the intelligent core, supporting unmanned cluster operations with compaction accuracy reaching ±0.25%, achieving internationally leading standards.

- Stringent Quality Control and Weather Resistance All genuine components undergo multidimensional testing: material composition analysis, extreme temperature validation (-40°C to 120°C), and 30% slope operation simulation, complying with national standards like GB/T 25684.13-2021. For instance, spray nozzles utilize 304 stainless steel with micro-pore arrangements ensuring uniform atomization. Paired with a multi-layer water filtration system, they intercept over 99% of impurities, significantly reducing nozzle clogging risks. Chassis components like the 350mm large-pitch tracks (China’s largest) employ Hardox wear-resistant steel, delivering over 15,000 hours of service life in rocky conditions.

Air Filter

Battery Switch

Clutch Release Bearing

Combination Meter

Cover

Driven Plate Assembly

Transmission Shaft

Vibration Motor

Shantui Road Roller Parts

Shantui Road Roller Components constitute an original equipment manufacturer (OEM) parts system developed by Shantui Co., Ltd. leveraging the industrial chain resources of Shandong Heavy Industry Group and over 70 years of engineering machinery R&D expertise. This system delivers full lifecycle solutions for high-grade highways, mining, water conservancy, and other applications, compatible with the entire SR10 to SR26MA series and select international brand equipment. Its core competitiveness manifests across three dimensions:

I. Technological Innovation and Product Matrix

- **Patented Technological Breakthroughs**

The independently developed compaction steel drum features a modular design. Its removable wheel sleeve and stud protection cap structure enables multi-purpose operation across diverse conditions, extending service life by 30% compared to traditional steel drums. The vibration system employs dual-frequency, dual-amplitude technology (27-35Hz), integrated with a closed hydraulic circuit and spoon-type lubrication design. It delivers 405kN of excitation force and achieves compaction depths exceeding 30cm, effectively handling complex media like clay and gravel. - **End-to-End Quality Control System**

Critical components like planetary gearboxes undergo carburizing and quenching processes, achieving ISO 6-grade gear precision with load-bearing capacity exceeding industry standards by 20%. Undercarriage parts (e.g., 350mm large-pitch tracks) utilize Hardox 500 wear-resistant steel with full hardening treatment, delivering over 15,000 hours of service life in rocky conditions. All components undergo validation in extreme temperatures (-40°C to 120°C) and simulated 30% gradient operations, complying with national standards including GB/T 25684.13-2021. - **Product Coverage and Compatibility**

Four core categories are established: Power Transmission Systems (engine components, dual-axle gearboxes), Hydraulic Systems (load-sensing valve assemblies, high-pressure hoses), Vibration Systems (high-frequency vibrators, damping mechanisms), and Undercarriage Systems (wear-resistant tires, sprinkler nozzles), totaling over 2,000 parts precisely matched to flagship models. For example, the vibratory wheel components for the SR22MA roller feature a patented reinforced tubular structure with a comprehensive service life exceeding 10,000 hours, making them suitable for heavy-duty applications such as airport runway construction.

Air Filter

Bearing

Diesel Fuel Filter Element

Fuel Filter Element

Oil Filter Element

Oil Water Separator

Primary Fuel Filter(Coarse Filter)

Steering Gear

Zoomlion Road Roller

Zoomlion roller components constitute an original equipment manufacturer (OEM) parts system developed by Zoomlion, leveraging over 70 years of construction machinery R&D expertise and global manufacturing capabilities. This system delivers efficient, durable solutions for full-scenario compaction operations on high-grade highways, airports, mines, and beyond. Covering critical systems including power transmission, hydraulics, vibration, and undercarriage, these components are compatible with the full range of ZL machinery models—such as YZC double-drum, ZRS dual-drive, and YZK single-drum rollers—while also supporting select international brands. Key aspects are detailed below across technology, product, service, and market dimensions:

I. Core Technology and Product Advantages

- Patented Breakthroughs The independently developed three-stage vibrating drum structure (e.g., Patent ZL201120183201.1) employs synchronous counter-rotation of inner and outer shafts. Utilizing oil-spoon lubrication and shock-free exciter technology, it achieves vertical vibration compaction with excitation forces ranging from 400 to 790 kN, compaction depths exceeding 30 cm, and a service life surpassing 10,000 hours. Hydraulic System Developed in deep collaboration with Rexroth, the hydraulic system achieves a response time ≤3ms and over 10% increased working pressure. Sealing performance remains leak-free after 1 million cycle tests.

- Integrated intelligent technology, such as the ZD131AS model equipped with smart compaction sensors, monitors parameters like compaction density and temperature in real time. It generates visual color-gradient maps to guide operations, improving compaction uniformity by 15% and reducing variability by 20% compared to traditional methods. IoT-enabled accessories support remote fault diagnosis and preventive maintenance. For instance, in African mining projects, remote diagnostics reduced equipment downtime by 40%.

- Stringent Quality Control and Weather Resistance Critical components like planetary gearboxes utilize carburizing and quenching processes, achieving ISO 6 gear precision with load capacity exceeding industry standards by 20%. Undercarriage parts (e.g., 350mm large pitch tracks) employ Hardox 500 wear-resistant steel, delivering over 15,000 hours of service life in rock conditions. All components undergo validation in extreme temperatures from -40°C to 120°C and simulated 30% slope operations, meeting international standards including CE and ISO 9001.

Pilot Filter Element P0-C0-02-02210(A)

Oil Water Separator Filter Element RF-AG-01-00110

Bucket Cylinder(ZL15-CD) Repair Kit

Air Respirator AB0210CA011A

Crane Parts

XCMG Crane Parts

XCMG Crane Components is the original equipment manufacturer (OEM) parts system developed by XCMG Group, leveraging 81 years of construction machinery R&D expertise and full-industry-chain integration capabilities. It delivers full-lifecycle solutions for construction, mining, energy, and other sectors, compatible with the entire range of XCMG crane models including QY truck cranes, XGC crawler cranes, and XCT all-terrain cranes. Through technological innovation, it also achieves compatibility and substitution for international brand equipment. The following outlines its strengths across technology, products, services, and market reach:

I. Core Technology and Product Advantages

- Independent R&D and global supply chain collaboration enable key components like the boom to utilize single-cylinder pin telescoping technology (Patent ZL201120183201.1). Combined with multi-stage pressure control and dual mechanical-hydraulic interlock mechanisms, this ensures safe and reliable telescoping system operation. Software-optimized single-cylinder pin motion trajectories achieve over 95% success rates. The powertrain integrates engines from international brands like Cummins and Volvo. Full-power matching technology optimizes fuel efficiency, reducing overall consumption by 5%-8%. The hydraulic system employs XCMG’s proprietary fully electronic hydraulic multi-port valve, enabling independent valve port control with a response time ≤3ms. Working pressure increases by over 10%, and sealing performance remains leak-free after 1 million cycle tests.

- Integrated smart technology incorporates IoT sensors for real-time monitoring of oil temperature, vibration frequency, boom load, and other parameters. A big data cloud platform provides predictive maintenance recommendations—for instance, XCMG reduced equipment downtime by 40% in African mining projects through remote diagnostics. Smart components support integration with XCMG’s “Xrea” industrial internet platform, enabling cloud-based storage and analysis of construction data to optimize operational workflows.

- Stringent Quality Control and Weather Resistance All components undergo validation in extreme temperatures from -40°C to 120°C and simulated 30% slope conditions, meeting ISO 9001, CE, and other international standards. Chassis components like the 350mm large-pitch crawler tracks utilize Hardox 500 wear-resistant steel, delivering over 15,000 hours of service life in rock conditions. Boom structural components are optimized through finite element analysis, achieving load-bearing capacity exceeding industry standards by 20%.

A810201206088 Controller

Clutch Booster 1264 1602510K

Fog Lamps

Icp6600 Monitor Spare Parts

Qy25K-I Cab Instrument Panel

Clutch Disc 819902278

Turning Light

Tansducer Pressure Sensor

SANY Crane Parts

Sany Heavy Industry Crane Components is an original equipment manufacturer (OEM) parts system developed by Sany Group leveraging core technologies and intelligent manufacturing capabilities in the global construction machinery sector. It provides full lifecycle solutions for construction, mining, energy, and other applications, compatible with the entire range of Sany equipment including SAC all-terrain cranes, SCC crawler cranes, and STC truck cranes, while also supporting select international brands. The following outlines key aspects across technology, products, services, and market dimensions:

I. Core Technology and Product Advantages

- Key components like the boom utilize independently developed single-cylinder pin telescoping technology (Patent ZL201120183201.1), integrated with multi-stage pressure control and dual mechanical-hydraulic interlock mechanisms to ensure safe and reliable telescoping. Software-optimized single-cylinder pin motion trajectories achieve over 95% success rates. The powertrain integrates engines from international brands like Cummins and Volvo. Full-power matching technology optimizes fuel efficiency, reducing overall consumption by 5%-8%. The hydraulic system employs XCMG’s proprietary fully electronic hydraulic multi-way valve, enabling independent valve port control with a response time ≤3ms. Working pressure increases by over 10%, and sealing performance remains leak-free after 1 million cycle tests.

- Smart technology integrates IoT sensors for real-time monitoring of oil temperature, vibration frequency, boom load, and other parameters. Through a big data cloud platform, it provides preventive maintenance recommendations. For instance, in an African mining project, Sany reduced equipment downtime by 40% via remote diagnostics. Smart components support integration with Sany’s “RootCloud” industrial internet platform, enabling cloud-based storage and analysis of construction data to optimize operational workflows.

- Stringent Quality Control and Weather Resistance All components undergo validation in extreme temperatures from -40°C to 120°C and simulated 30% slope conditions, meeting ISO 9001, CE, and other international standards. Chassis components like the 350mm large-pitch crawler tracks utilize Hardox 500 wear-resistant steel, delivering over 15,000 hours of service life in rock conditions. Boom structural components are optimized through finite element analysis, achieving load-bearing capacity exceeding industry standards by 20%.

Sany 60226703 Front Wiper Blade

Sany 897606-9430 Sensor

14194803 Low Temperature Steering Cylinder

Sany 131401010001A006 Brake Pad Assembly

Sany 897602-0353 Thermostat

Sany 897605-9468 Fuel Injection Pump Assembly

Sany 160102060020B002 Turbocharger

Sany 160102090018B001 Thermostat

Zoomlion Crane Parts

Zoomlion Crane Components is an original equipment manufacturer (OEM) parts system developed by Zoomlion, leveraging over 70 years of engineering machinery R&D expertise and global manufacturing capabilities. It delivers full lifecycle solutions for construction, mining, energy, and other applications, compatible with the entire product range including ZAT all-terrain cranes, ZCC crawler cranes, TC series tower cranes, and select international brands. The following sections explore technical, product, service, and market dimensions:

I. Core Technology and Product Advantages

- Patented Innovation: The independently developed boom vibration control technology (Patent ZL201310642578.2) employs active vibration reduction algorithms to reduce boom vibration amplitude by over 80%. This enables millimeter-level precision lifting for strategic projects like the Hualong One nuclear power initiative. The power system employs hybrid drive technology (e.g., ZAT2200VE863 model), combining fuel and electric dual modes to reduce fuel consumption during lifting operations by 35% compared to traditional models, saving over 100,000 yuan annually in fuel costs. The hydraulic system, developed in deep collaboration with Rexroth, achieves a response time ≤3ms, with sealing performance tested for 1 million cycles without leakage.

- Integrated smart technology employs IoT sensors for real-time monitoring of oil temperature, vibration frequency, boom load, and other parameters. The “Zoomlion e-Manager” platform delivers preventive maintenance recommendations—for instance, reducing equipment downtime by 40% in African mining projects through remote diagnostics. Smart accessories support integration with XCMG’s “Xrea” industrial internet platform, enabling cloud-based storage and analysis of construction data.

- Stringent Quality Control and Weather Resistance Critical components like boom structural parts utilize Q690D high-strength steel, optimized via finite element analysis to exceed industry load standards by 20%. Undercarriage components (e.g., 350mm large-pitch tracks) employ Hardox 500 wear-resistant steel, delivering over 15,000 hours of service life in rock conditions. All components undergo validation in extreme temperatures from -40°C to 120°C and simulated 30% gradient operations, meeting international standards including CE and ISO 9001.

Combination Tail Lamp Left(ZTC-Applicable)

Four Stage Gear Pump JHP2063-2050-2040-GJ1010

Fuel Sensor

Hoist Motor A6V107HA2FZ1070

Outrigger TC6517C.15B

Slider 1087-470040-1010

Tire Assembly 12.00R24

Water Removal With Confidence Filter

Milling Machine Parts

XCMG Milling Machine Parts

XCMG milling machine components constitute an original equipment manufacturer (OEM) parts system developed by XCMG Group, leveraging 81 years of construction machinery R&D expertise and full-industry-chain integration capabilities. This system delivers full-lifecycle solutions for scenarios including highway maintenance, airport upgrades, and municipal engineering projects, compatible with the entire XM series milling machine lineup (e.g., XM1005KIV, XM1305KIV) and select international brand equipment. The following outlines key aspects from technical, product, service, and market perspectives:

I. Core Technology and Product Advantages

- Patented Quick-Change Cutter Head System (Patent No. to be supplemented)

This independently developed, modular design boosts cutter replacement efficiency by 50%, reduces cutting resistance by 30%, and enhances wear resistance by 40% compared to conventional cutter heads. Milling drums incorporate oil-spoon lubrication technology, passing 100,000 load cycle tests with a comprehensive lifespan exceeding 10,000 hours, compatible with 27-35Hz multi-frequency compaction requirements. The hydraulic system, developed in deep collaboration with Rexroth, achieves response times ≤3ms, over 10% increased working pressure, and seal performance verified through 1 million cycle tests with zero leakage. - The integrated intelligent depth control system stores and recalls three sets of milling depth parameters, digitally displayed via a 7-inch color monitor with ±1mm depth adjustment accuracy. IoT sensors monitor oil temperature, milling speed, and other data in real time, enabling remote fault diagnosis and preventive maintenance. For instance, in African mining projects, XCMG reduced equipment downtime by 40% through remote diagnostics.

- Stringent Quality Control and Weather Resistance Critical components like planetary gearboxes utilize carburizing and quenching processes, achieving ISO 6 gear precision with load capacity exceeding industry standards by 20%. Undercarriage parts (e.g., 350mm large pitch tracks) employ Hardox 500 wear-resistant steel, delivering over 15,000 hours of service life in rock conditions. All components undergo validation in extreme temperatures from -40°C to 120°C and simulated 30% slope operations, meeting international standards including CE and ISO 9001.

803093703 Main Hydraulic Manifold

XCMG S00006912+01 Fuel Injection Pump

860165404 Rotating Speed Sensor

XCMG 384102027 Left Shaft

XCMG 803068865 Cylinder

XCMG D15-000-41+C Oil Pump Group

XCMG D061-002-34B Crankshaft Damper

XCMG 803687261 Harness

SANY Milling Machine Parts

Sany Milling Machine Components is an original equipment manufacturer (OEM) parts system developed by Sany Heavy Industry, leveraging its core technologies in road machinery and global manufacturing capabilities. It provides full lifecycle solutions for scenarios such as highway maintenance, airport renovation, and municipal engineering, compatible with the entire spectrum of SCM series milling machines (e.g., SCM1300C-8S, SCM2000C-8S) and select international brand equipment. The following outlines key aspects from technical, product, service, and market perspectives:

I. Core Technology and Product Advantages

- Patented Quick-Change Cutter Head System (Patent No. CN217104638U)

This independently developed, modular design boosts cutter replacement efficiency by 50%, reduces cutting resistance by 30%, and enhances wear resistance by 40% compared to traditional cutter heads. Milling drums incorporate oil-spoon lubrication technology, achieving over 10,000 hours of comprehensive service life after 100,000 load cycle tests, compatible with 27-35Hz multi-frequency compaction requirements. The hydraulic system, developed in deep collaboration with Rexroth, delivers response times ≤3ms, over 10% increased working pressure, and seal performance verified through 1 million cycle tests with zero leakage. - The integrated intelligent depth control system stores and recalls three sets of milling depth parameters, digitally displayed via a 7-inch color monitor with ±1mm depth adjustment accuracy. IoT sensors continuously monitor oil temperature, milling speed, and other data, enabling remote fault diagnosis and preventive maintenance. For instance, in a provincial road project in South Africa, Sany reduced equipment downtime by 40% through remote diagnostics.

- Stringent Quality Control and Weather Resistance

Critical components like planetary gearboxes utilize carburizing and quenching processes, achieving ISO 6 gear precision with load capacity exceeding industry standards by 20%. Chassis components (e.g., 350mm large pitch tracks) utilize Hardox 500 wear-resistant steel, delivering over 15,000 hours of service life in rock conditions. All accessories undergo validation in extreme temperatures (-40°C to 120°C) and simulated 30% gradient operations, meeting international standards including CE and ISO 9001.

Rear Headlamp

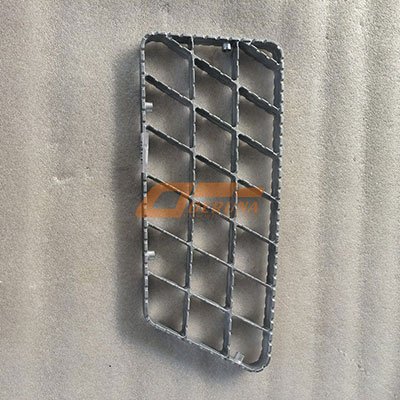

Punching Plate

Hydraulic Pump Gear

Fan Belt

Asphalt Finisher Parts

SANY Asphalt Finisher Parts

Sany Asphalt Paver Components is an original equipment manufacturer (OEM) parts system developed by Sany Heavy Industry, leveraging its core technologies in road machinery and global manufacturing capabilities. It provides full lifecycle solutions for high-grade highways, municipal projects, airport runways, and other applications, compatible with the entire SA series of pavers (such as SAP200C-10, SAP90C-10S) and select international brand equipment. Its core competitiveness manifests across three dimensions:

I. Technological Innovation and Product Matrix

- Breakthrough Core Technologies

The independently developed modular screed features a three-section structure (Patent ZL201310642578.2). Its removable wheel sleeves and protrusion protection sleeves enable multi-purpose use for both asphalt and stabilized base construction, extending service life by 30% compared to traditional steel wheels. The screw distributor features variable-pitch blades (sparse front, dense rear) and a segmented structure. Combined with ultrasonic material level sensors, it reduces aggregate segregation by over 40% and achieves paving smoothness of ±3mm/3m. The hydraulic system, developed in deep collaboration with Rexroth, boasts a response time ≤3ms and seal performance tested leak-free through 1 million cycles. - Smart Technology Integration Equipped with 3D digital paving systems (e.g., SA series), it achieves ±1mm thickness control precision through BeiDou positioning and laser leveling technology. IoT sensors monitor parameters like oil temperature and auger speed in real time, enabling remote fault diagnosis and preventive maintenance. For instance, remote diagnostics reduced equipment downtime by 40% during the Hunan Changzhou Expressway project.

- Stringent Quality Control and Weather Resistance Critical components like planetary gearboxes employ carburizing and quenching processes, achieving ISO 6 gear precision with load capacity exceeding industry standards by 20%. Chassis parts (e.g., 350mm large-pitch tracks) utilize Hardox 500 wear-resistant steel, delivering over 15,000 hours of service life in rock conditions. All components undergo validation in extreme temperatures from -40°C to 120°C and simulated 30% slope operations, meeting international standards including CE and ISO 9001.

Paver 400 Right Handed Blade

Paver Left Rotation Anti Segregation Blade

.jpg)

Paver Track Plates(131902050002)

Right Handed Anti Segregation Blades

Dump Truck Parts

Sinotruk Dump Truck Parts

Sinotruk dump truck parts are specifically engineered to ensure the durability, uptime, and efficient operation of heavy-duty dump trucks in harsh working conditions. Genuine parts cover engines, transmissions, chassis, hydraulic systems, and electrical systems. With precise compatibility, superior materials and craftsmanship, and reliable performance, they guarantee stable vehicle operation in environments such as mines and construction sites, effectively extending equipment lifespan and maximizing operational efficiency.

71°C Thermostat Without Housing VG1500060117

Heater Radiator WG1642822064

Inner Door Handle WG1642340033

Release Bearing WG9725160560

Steering Lever(Bipod) Left Hand End M20 Taper 2427 Mm AZ9160410121

Steering Wheel AZ9719470100

Transmission Cranks WG9900241004

Wiper Arm AZ1642740010

Shacman Dump Truck Parts

Shacman Dump Truck Parts are genuine components specifically engineered for Shacman’s robust dump trucks, such as the X3000, X6000, and other series. These parts are designed to withstand the harsh conditions of mining, construction, and heavy-duty transport, ensuring durability, reliability, and optimal performance. From engine and transmission systems to chassis, braking, and hydraulic components, each part guarantees perfect compatibility and extended service life, minimizing downtime and maximizing productivity on demanding job sites.

Air Conditioning Compressor(Wedge-Type) DZ13241824110

Cab Hydraulic Lock X3000 DZ13241440085

Cab Lift Cylinder X3000 DZ97259820103

Electric Tachometer DZ9100586012

Fan Clutch WP10 Euro4 612600062120

Footboard F3000 Right(Middle Step) Aluminum DZ13241240674

Front Brake Pads 163X183 (8 Holes) + 163X215 (10 Holes) 81.50221.0535

WP12 X3000 Exhaust Valve Rocker Bridge 1000495068

Beiben Dump Truck Parts

Beiben Dump Truck Parts are genuine OEM components specifically engineered for Beiben heavy-duty dump trucks. Renowned for their exceptional durability, precise compatibility, and reliable performance, these parts cover critical assemblies including the engine system, chassis structure, transmission, cab, and hydraulic lifting system. They ensure efficient and stable operation in demanding environments such as mines and construction sites, effectively extending equipment lifespan while maximizing uptime and operational efficiency.

Wiper Arm Assembly LBZF56GB3MA007798

Tail Light Right A5205440203

Start Key Switch 0014621130000072eP6EDA

Right Rear View Assembly A500-810-61-16

Propeller Shaft Assembly A-699-410-02-02

Left Trim Staip(Mud Guard) A571-881-08-01

Brake Lining Rear F2217064

62X162 MM Spider Bearing

Why Choose Us?

Frequently Asked Questions About Road Equipment Parts

Replace aged or damaged seals according to model specifications (e.g., Gleason seals, O-rings).

Inspect for loose pipe connections or failed seals; tighten or replace promptly.

Possible causes include damaged vibration motors or hydraulic system failures. Inspect and repair as needed.

Cutter heads may be damaged beyond service limits, affecting the cutter holder, or may encounter hard objects like rebar during milling. Replace cutter heads regularly and follow proper operating procedures.

Choose high-quality wear-resistant steel (e.g., Hardox steel) to enhance durability and paving smoothness.

Select anti-twist wire ropes and install them correctly. Replace immediately if wear exceeds standards (e.g., broken wires, reduced diameter).

Carefully inspect part dimensions before installation to ensure compatibility with the equipment. Installation must be performed by qualified technicians.

Normal wear follows a consistent pattern; frequent failures or premature damage may indicate quality issues.

Regularly inspect and replace engine oil, air filters, etc., to ensure proper engine operation.

Material quality and specification compatibility; select suppliers with proven reliability.

Resources Center-Road Equipment Parts Catalog

XCMG Excavator Parts

Shantui Excavator Parts

SANY Excavator Parts

Zoomlion Excavator Parts

Shantui Loader Parts Catalog

Zoomlion Loader Parts Catalog

- Zoomlion Wheel Loader Parts Catalog

- Zoomlion Crawler Loader Parts Catalog

- Zoomlion Skid Steer Loader Parts Catalog

- Zoomlion Compact Track Loader Parts Catalog

- Zoomlion ZWL75GE Loader Parts Catalog

- Zoomlion ZS085V Loader Parts Catalog

- Zoomlion ZS090V Loader Parts Catalog

- Zoomlion ZS120V Loader Parts Catalog

XCMG Bulldozer Parts Catalog

Zoomlion Bulldozer Parts Catalog

Shantui Bulldozer Parts Catalog

Zoomlion Bulldozer Parts Catalog

XCMG Road Roller Parts Catalog

- XCMG Single Drum Vibratory Roller Parts Catalog

- XCMG Double Drum Vibratory Roller Parts Catalog

- XCMG Three-wheel Static Roller Parts Catalog

- XCMG Light Compaction Equipment Parts Catalog

- XCMG Pneumatic Roller Parts Catalog

- XCMG Soil Compactor Parts Catalog

- XCMG Backfill Compactor Parts Catalog

- XCMG Trench Compactor Parts Catalog

- XCMG New Energy Roller Parts Catalog

Shantui Road Roller Parts Catalog

Sany Road Roller Parts Catalog

- Sany Single Drum Roller (Single Drive) Parts Catalog

- Sany Single Drum Roller (Dual Drive) Parts Catalog

- Sany Tandem Drum Roller Parts Catalog

- Sany Pneumatic Tyre Roller Parts Catalog

- Sany SPR300C-10 Pneumatic Tyre Roller Parts Catalog

- Sany SSR260AC-8H Single Drum Roller Parts Catalog

- Sany STR140C-10 Tandem Drum Roller Parts Catalog

- Sany SSR120C-10S (Euro Ⅲ) Single Drum Roller Parts Catalog

Shantui Road Roller Parts Catalog

XCMG Asphalt Finisher Parts Catalog

Shantui Asphalt Finisher Parts Catalog

Sany Asphalt Finisher Parts Catalog

Shantui Asphalt Finisher Parts Catalog

XCMG Milling Machine Parts Catalog

- XCMG XM2005K(Stage V) Milling Machine Parts Catalog

- XCMG XM2005KⅢ Milling Machine Parts Catalog

- XCMG XM1505F Milling Machine Parts Catalog

- XCMG XM1305K Milling Machine Parts Catalog

- XCMG XM505 Milling Machine Parts Catalog

- XCMG XM505K(Stage V) Milling Machine Parts Catalog

- XCMG XM1005F Milling Machine Parts Catalog

- XCMG XM1205F Milling Machine Parts Catalog

Sany Milling Machine Parts Catalog

Shantui Milling Machine Parts Catalog

- Shantui SMT50-C7 Cold Milling Machine Parts Catalog

- Shantui SMT50-C7N Cold Milling Machine Parts Catalog

- Shantui SMT100-C7 Cold Milling Machine Parts Catalog

- Shantui SMT200M-C7 Cold Milling Machine Parts Catalog

- Shantui SMT100M-C6 Cold Milling Machine Parts Catalog

- Shantui SMT50-C6N Cold Milling Machine Parts Catalog