Loader Parts

Spare Parts

Contact Us

Loader Parts

XCMG Loader Parts

- XCMG Loader Parts embodies the technical prowess of XCMG, a global construction machinery giant, and is recognized for its full-system coverage, rigorous quality control, and efficient global service support.

- Its product portfolio spans core components across key systems of loaders: power transmission parts such as 6-blade turbine torque converters (boosting fuel efficiency by 15%) and forged axle assemblies with Rockwell hardness 58-62 HRC ; hydraulic system components including award-winning XOV25 multi-way valve castings (with valve hole bending degree <1mm) and chrome-plated cylinder rods (0.05μm surface finish) ; electrical modules like J1939-compatible CANbus controllers and -40°C to 150°C operational temperature sensors ; as well as structural parts such as 400 HB hardness abrasion-resistant bucket liners .

- Quality is rooted in decades of expertise: backed by 78+ years of R&D , every genuine part undergoes 23 rigorous inspections including material composition analysis and load cycle simulation . Manufactured with proprietary alloys and automated production lines (e.g., HWS/DISA intelligent molding systems) , key components like hydrostatic pumps (320 bar max pressure) and dust-proof alternators (IP69K rating) deliver stable performance in extreme environments such as mines and high-dust areas, with core castings validated by 200,000-hour bench tests .

- The full range is certified under ISO 9001 and IATF 16949 quality systems .

With precise compatibility, these parts are tailor-made for XCMG’s mainstream loader series, including LW300KV, ZL50G, and LW500FN , ensuring factory-grade fit and performance restoration. Relying on a global network covering 183 countries and regions , complemented by 46 overseas spare part centers and 3 billion RMB worth of standing inventory , XCMG enables near-instant delivery and 24/7 technical support via its official parts mall . Combined with lifetime technical assistance , it has become the preferred choice for loader maintenance and OEM matching worldwide.

Air Filter K2640

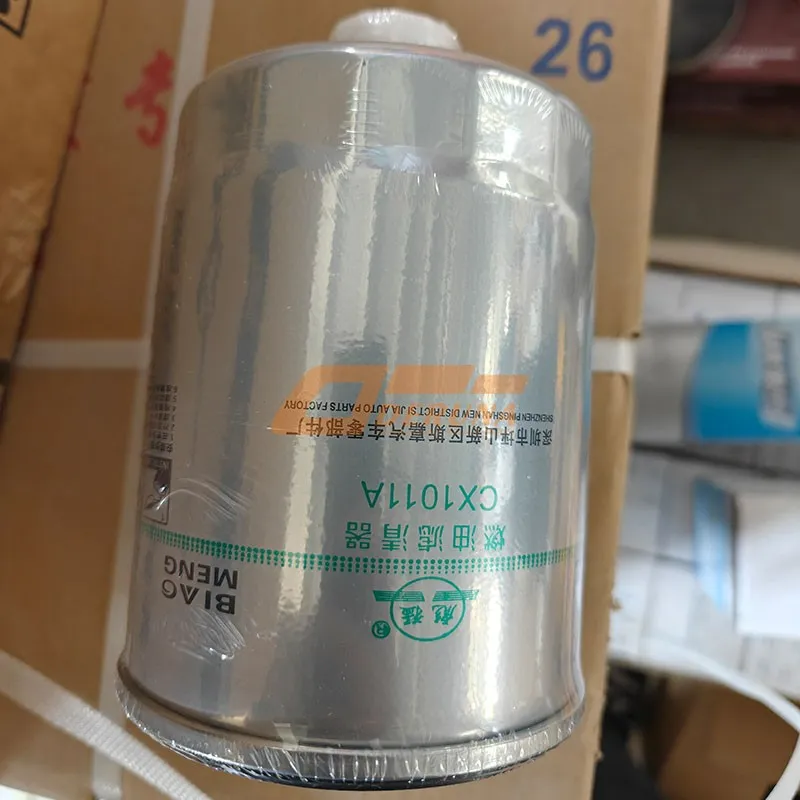

C85AB-1W8633AB Fuel Filter

C85AB-85AB302+B Fuel Water Separator

860159366 Brake Disc Pad

C06Bl-M7W5698+A Belt Tensioner Assembly

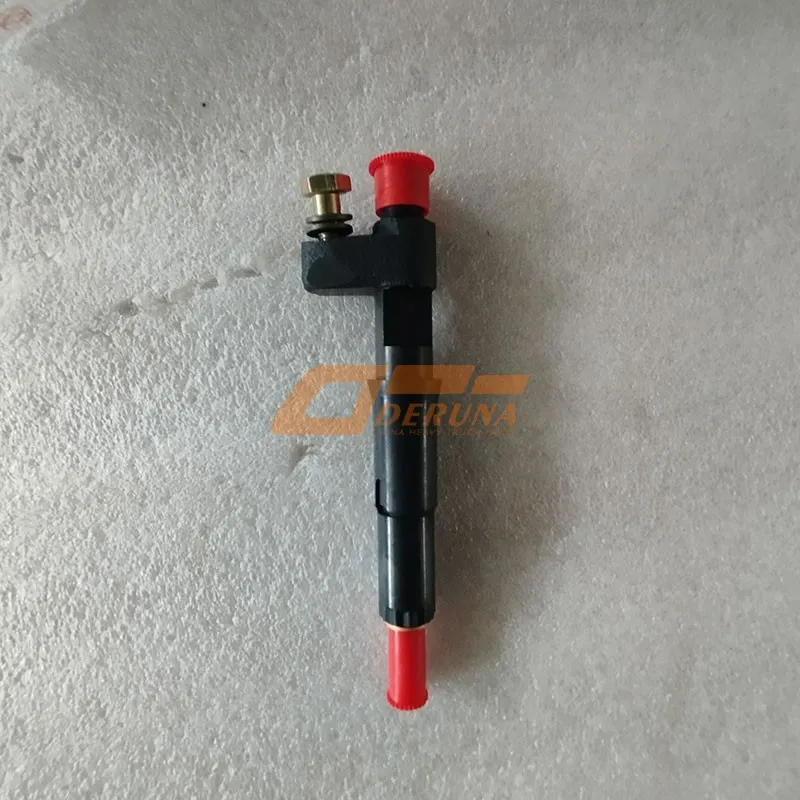

C26AB-26AB701 Fuel Injector

860114222 Gimbal Assy(Spider Assy)

S00017067+02+SH Alternator(Generator)

SANY Loader Parts

Includes transmission, hydraulic, and new energy modules (IP67 motors, liquid-cooled batteries), catering to both fuel and electric loader requirements; key components undergo 2000-hour endurance testing, capable of operating in extreme environments from -30°C to 50°C, with braking energy recovery technology reducing energy consumption by 18%; Compatible with Sany SW series (fuel-powered SW936K1, electric SW956E-Super); leverages a global network of 1,900+ service centers, 2,700+ engineers, and TVH spare parts partnerships to deliver efficient delivery and after-sales support.

Sany Brake Valve 60232819

Connecting Board Footboard 13486251

Sany Converter 60222546

Sany Fuel Fine Filter Core 60321274

Sany Fuel Sensor 60246822

Sany Pedal Assy SW405K1.1.8-13839425

Sany Safety Catridge Of Air Filter 60207264

Sany Video System Display 60105154

Shanui Loader Parts

Shantui loader parts are manufactured by Shantui based on decades of industry expertise, offering core advantages in heavy-duty durability, comprehensive system coverage, and high cost-effectiveness. Key features include:

- Full System Coverage: Encompasses core components of the loader’s critical systems, including: Hydraulic System (25MPa high-pressure gear pumps, integrated multi-way valves with ≤0.5% pressure loss, chrome-plated cylinders with 0.08μm surface precision), structural wear parts (Mn13 high-manganese steel 400HB wear-resistant bucket liners, fully welded reinforced boom, anti-slip tires), and electrical auxiliary components (voltage regulator compatible with -30°C to 80°C, IP67 waterproof sensors, aluminum alloy radiator with 15% higher cooling efficiency), meeting both routine maintenance and overhaul requirements.

- Rigorous Quality Assurance: All genuine parts are manufactured to Shantui OEM standards, undergo 16 quality inspections (including material analysis, pressure cycle simulation, and low-temperature start-up testing), and are ISO 9001 certified. Core components (such as drive axles and hydraulic pumps) withstand harsh environments like open-pit mines and high-dust conditions, backed by a 1-2 year warranty.

- Precision Compatibility & Efficient Service: Precisely matched to Shantui’s mainstream loader series (3-ton SL30W, 5-ton SL50W, 6-ton SL60W), ensuring 100% factory-level fitment and operational efficiency. Leveraging a domestic service network covering 31 provinces and municipalities, along with overseas distribution centers in Southeast Asia, the Middle East, and Africa, we deliver timely parts supply and 24/7 technical support. This makes us a reliable choice for loader users in construction, mining, and logistics industries.

Air Boost Pump

Bucket Teeth

Frame And Boom Rear Axle

Loader Tires (Standard Edition)

Pilot Twin Pump

Right Tooth

Steering Cylinder

Working Pump

Zoomlion Loader Parts

Zoomlion loader parts are professional accessories developed by Zoomlion, a global leader in construction machinery. Their core strengths lie in comprehensive system coverage, robust heavy-duty performance, and intelligent compatibility. These advantages can be summarized in three key aspects:

- Comprehensive System Product Matrix: Covers core components of loader critical systems, including: Hydraulic System (31.5MPa high-pressure main pump, corrosion-resistant chrome-plated integrated manifold valve, imported sealed cylinders with high-temperature leak resistance), Structural Wear Components (NM450 wear-resistant steel bucket liners with twice the lifespan of standard steel, stress-relieved welded boom for enhanced durability, puncture-resistant construction tires for gravel applications), and intelligent electrical components (CAN bus controller compatible with Zoomlion’s smart maintenance platform, sensors adapted for -35°C to 85°C temperature range, high-efficiency thermally controlled electric fan). These features meet diverse loader maintenance requirements across industries.

- Rigorous Quality Assurance: All genuine parts manufactured to Zoomlion OEM standards, undergo 18 inspections (including material spectral analysis, heavy-duty cycle testing, low-temperature endurance verification), and certified to ISO 9001, CE, and TUV. Core components (e.g., wet brake axles, hydraulic pumps) withstand harsh conditions like high dust and continuous heavy loads, backed by 1-2 year warranties.

- Precision Compatibility & Global Service: Precisely matched for Zoomlion’s mainstream loader series (5-ton ZL50GV, 3-ton LW300FV, 6-ton ZL60G), ensuring 100% factory-level fitment and operational efficiency. Leveraging a global service network (with local parts warehouses in Southeast Asia, Europe, and South America, plus domestic coverage across 32 provinces), we deliver timely parts and 24/7 technical support, making us the reliable choice for loader users worldwide.

Water Filter Cartridge NP0203030031

Safety Filter Cartridge A02-03720

Respirator Filter Cartridge PO-CO-02-02760

Pilot Filter Element PO-CO-02-02790

Oil Filter Element PF-CO-01-031100

Fuel Filter Element FO1-01310(6)

Fuel Coarse Filter Element NP0203020109

Boom Cylinder(ZL21-DB) Repair Kit

Why Choose Us?

Frequently Asked Questions About Loader Parts

Replace aged or damaged seals according to model specifications (e.g., Gleason seals, O-rings).

Inspect for loose pipe connections or failed seals; tighten or replace promptly.

Possible causes include damaged vibration motors or hydraulic system failures. Inspect and repair as needed.

Cutter heads may be damaged beyond service limits, affecting the cutter holder, or may encounter hard objects like rebar during milling. Replace cutter heads regularly and follow proper operating procedures.

Choose high-quality wear-resistant steel (e.g., Hardox steel) to enhance durability and paving smoothness.

Select anti-twist wire ropes and install them correctly. Replace immediately if wear exceeds standards (e.g., broken wires, reduced diameter).

Carefully inspect part dimensions before installation to ensure compatibility with the equipment. Installation must be performed by qualified technicians.

Normal wear follows a consistent pattern; frequent failures or premature damage may indicate quality issues.

Regularly inspect and replace engine oil, air filters, etc., to ensure proper engine operation.

Material quality and specification compatibility; select suppliers with proven reliability.

Resources Center-Loader Parts Catalog

XCMG Loader Parts

SANY Loader Parts

- SANY Wheel Loader Parts Catalog

- SANY Backhoe Loader Parts Catalog

- SANY Skid Steer Loader Parts Catalog

- SANY SW405K Loader Parts Catalog

- SANY SW966K1 Loader Parts Catalog

- SANY SW978K1 Loader Parts Catalog

- SANY BHL75 Loader Parts Catalog

- SANY BHL95 Loader Parts Catalog

- SANY BHL105 Loader Parts Catalog

- SANY ST230V (US) Loader Parts Catalog

Shantui Loader Parts

Zoomlion Loader Parts

- Zoomlion Wheel Loader Parts Catalog

- Zoomlion Crawler Loader Parts Catalog

- Zoomlion Skid Steer Loader Parts Catalog

- Zoomlion Compact Track Loader Parts Catalog

- Zoomlion ZWL62G Loader Parts Catalog

- Zoomlion ZWL75G Loader Parts Catalog

- Zoomlion ZWL75GE Loader Parts Catalog

- Zoomlion ZS085V Loader Parts Catalog

- Zoomlion ZS090V Loader Parts Catalog

- Zoomlion ZS120V Loader Parts Catalog