Bulldozer Parts

Spare Parts

Contact Us

Bulldozer Parts

XCMG Bulldozer Parts

- XCMG bulldozer components form an exclusive parts system developed by XCMG Group, a global leader in construction machinery, for its bulldozer series. Leveraging the Group’s 78 years of R&D expertise and manufacturing prowess in the construction machinery sector, this system delivers OEM-quality parts solutions for demanding applications such as large-scale earthmoving operations. As a vital component of XCMG’s comprehensive construction machinery parts ecosystem, this series covers core bulldozer systems and wear-prone components, compatible with multiple mainstream models. It serves as a critical foundation for ensuring efficient equipment operation.

- Centering on stringent quality control, every genuine part undergoes 23 rigorous inspection procedures. These include material composition analysis, load cycle simulation testing, validation under extreme temperatures from -40°C to 65°C, and vibration resistance certification. Compliance with international standards like ISO 9001 and MIL-STD-810G ensures enduring durability in harsh environments like mining and infrastructure projects. Core offerings span three critical systems: – Power transmission components like specialized transmissions and forged gears utilize proprietary alloy materials and innovative transmission configurations to enhance transmission efficiency and fuel economy. – Hydraulic system components, including high-precision cylinders and load-sensing control valves, feature chrome-plated piston rods with 0.05μm surface finish and <3ms response times to guarantee operational precision. Additionally, the portfolio includes weather-resistant electrical controllers, sensors, and undercarriage components like track assemblies and idler wheels, comprehensively addressing equipment maintenance needs.

- Leveraging XCMG’s global service network, XCMG Bulldozer Parts delivers genuine compatibility assurance, lifetime technical support, and efficient worldwide distribution. Its quality and compatibility not only extend bulldozer lifespan and reduce downtime costs but also demonstrate XCMG’s self-reliant technological prowess in core components, making it a trusted choice for global users to maintain equipment performance.

Bulldozer Cab Drive Cabin

Air Suspension Seat

Gearshift Valve 16Y-75-10000

Bit End 16Y-81-00002/16Y-81-00003

Monitor Display Monitor Panel

Pinion Shaft 154-15-33240

Universal Joint Assy 16Y-12-00000

Shaft Coupling 16Y-15-00009

SANY Bulldozer Parts

- SANY Bulldozer Components is the original equipment manufacturer (OEM) parts system developed by SANY Heavy Industry for global earthmoving projects. Leveraging the Group’s core R&D capabilities in construction machinery and its global manufacturing footprint, it delivers compatible and durable component solutions for demanding applications in mining, infrastructure, agriculture, forestry, and water conservancy. As a core component of SANY Construction Machinery’s full lifecycle service, these parts cover critical systems including bulldozer power, hydraulics, and undercarriage, serving as the essential foundation for sustained, efficient equipment operation.

- This series leverages “technology integration + stringent quality control” as its core strengths. All genuine parts undergo multidimensional performance validation and comply with international quality standards such as ISO 9001 and TS 16949. Core components leverage global premium supply chain resources, including Rexroth hydraulic pumps and valves, Cummins engine-specific assemblies, and Sany’s proprietary planetary gearboxes. The latter incorporates Schaeffler bearings and specialized alloy steel treated with carburizing and quenching processes, achieving industry-leading gear precision and load-bearing capacity. For extreme operating conditions, wear-prone components like dozer blades and track pads utilize Hardox 500 special wear-resistant steel with impact-resistant coatings. Combined with Sany’s patented dual-telescopic arm hinge structure for dozer blades, this enables flexible multi-angle operation and extends service life by over 30% compared to conventional parts.

- In terms of product coverage, three core systems have been established: – Power transmission components like transmission assemblies and forged gears utilize full-power matching technology to optimize fuel efficiency; – Hydraulic system components, including high-precision cylinders and load-sensing control valves, ensure operational precision with response times under 3ms; For chassis systems, track assemblies and idler wheels feature monocoque bogie designs that minimize soil accumulation and travel wear, achieving a theoretical lifespan 1.2-1.5 times longer than domestic competitors. Additionally, the dedicated lubricant series (engine oil, hydraulic oil, etc.) employs precision formulations to reduce equipment failure risks and maintenance costs.

Carrier Roller

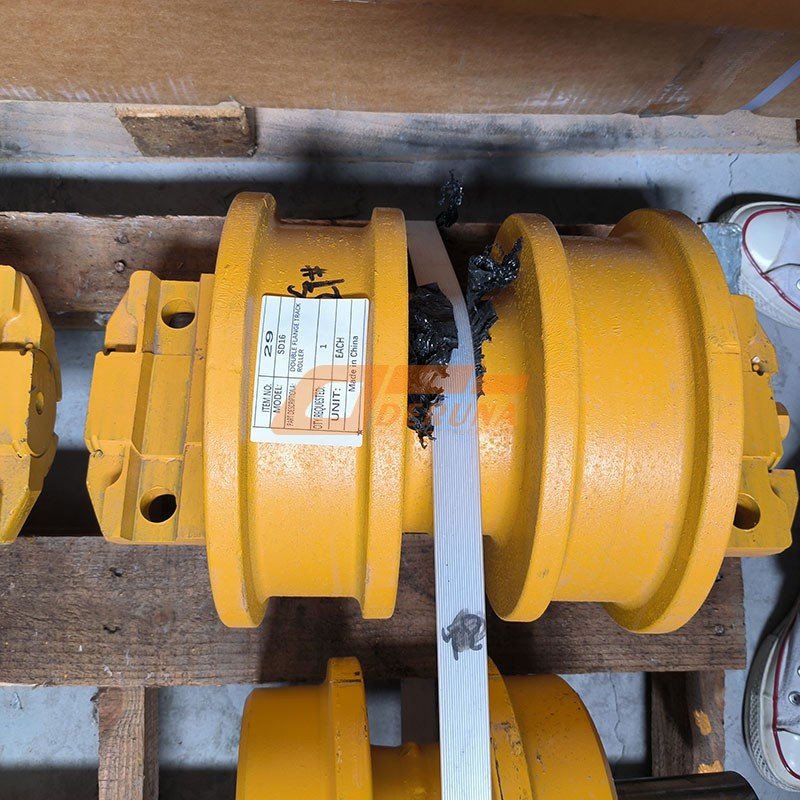

Double Flange Track Roller

Engine Oil Dipstick

Excitor

Fan Belt

Generator

Starter Motor

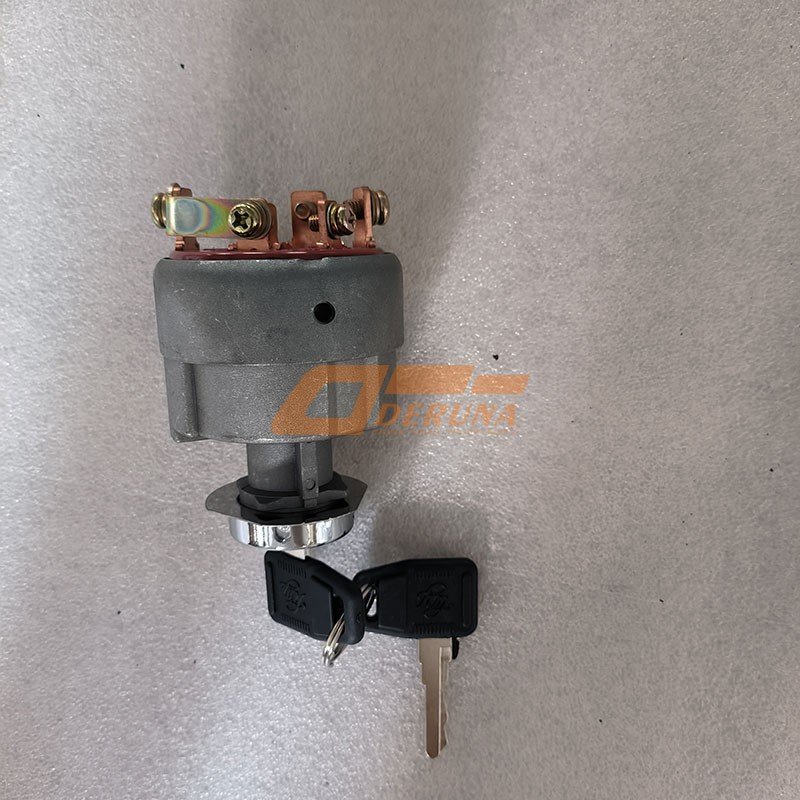

Start Switch

Shantui Bulldozer Parts

- Shantui bulldozer components form an original equipment manufacturer (OEM) parts system developed by Shantui Co., Ltd. leveraging over 70 years of construction machinery expertise and Shandong Heavy Industries’ “golden industrial chain.” This system delivers solutions that combine adaptability and durability for demanding environments like mining and infrastructure projects, serving as the core operational support for over one million Shantui machines worldwide.

- Its core strengths lie in proprietary technology and comprehensive quality control across the entire supply chain: The transmission system features key components like the SD52 modular transmission assembly (equipped with a dual-clutch lock-up torque converter, reducing overall fuel consumption by over 5%) and the YJ365 torque converter (with tensile strength exceeding industry standards by 20%). The undercarriage system sets benchmarks with its full range of lubricated tracks (50% longer lifespan than traditional tracks, holding 10 patents), China’s largest 350mm pitch tracks (exceeding 15,000 hours in rock conditions), and fully hardened mining-grade “four-wheel” components. Seal reliability and wear resistance are reinforced through multiple manufacturing processes. Product categories cover critical systems including powertrain, hydraulics, and undercarriage, compatible with the full range of SD08 to SD90 models from Shantui, as well as equipment from leading brands like Komatsu and Caterpillar.

- Service support leverages a global network of “port backbone warehouses + regional hub warehouses” spanning over 120 countries and regions. Domestic coverage includes a 2-year/3,000-hour warranty, extended to 18 months overseas, complemented by 48-hour response times and parts consignment policies to significantly reduce downtime costs. Its technical prowess and reliability have been validated in extreme environments across over 95% of Belt and Road countries, Canadian mines, and African infrastructure projects, achieving import substitution for multiple core components.

TP1000588583 Air Filter

TP1000442956 Fuel Filter (Fine Filter)

TP612600114993 Fuel Filter

16Y-15-07000 Transmission Magnetic Filter Element

Tooth Tip

Transmission Control Valve

Universal Joint Assembly

Belt Tensioner Pulley

Why Choose Us?

Frequently Asked Questions About Bulldozer Parts

Replace aged or damaged seals according to model specifications (e.g., Gleason seals, O-rings).

Inspect for loose pipe connections or failed seals; tighten or replace promptly.

Possible causes include damaged vibration motors or hydraulic system failures. Inspect and repair as needed.

Cutter heads may be damaged beyond service limits, affecting the cutter holder, or may encounter hard objects like rebar during milling. Replace cutter heads regularly and follow proper operating procedures.

Choose high-quality wear-resistant steel (e.g., Hardox steel) to enhance durability and paving smoothness.

Select anti-twist wire ropes and install them correctly. Replace immediately if wear exceeds standards (e.g., broken wires, reduced diameter).

Carefully inspect part dimensions before installation to ensure compatibility with the equipment. Installation must be performed by qualified technicians.

Normal wear follows a consistent pattern; frequent failures or premature damage may indicate quality issues.

Regularly inspect and replace engine oil, air filters, etc., to ensure proper engine operation.

Material quality and specification compatibility; select suppliers with proven reliability.